|

...World Wide Distributor of Beryllium-Free Copper Alloys...

Manufacturer of Standard & Custom Components

![]()

Site Updated Often! To ensure proper viewing please Refresh page &

MAKE SURE YOUR BROWSER IS SET TO UPDATE AT EACH VISIT

![]()

MoldStar®150 & MoldStar®90 Alloys

Machining Recommendations

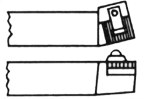

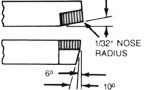

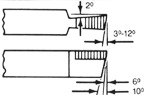

| TURN & BORE | ||||||||||||||||||||||

|

|

|||||||||||||||||||||

|

|

|||||||||||||||||||||

|

||||||||||||||||||||||

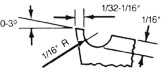

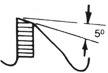

| REAM | |

|

|

|

|

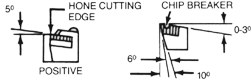

| TAP | |||||||||||

|

|

||||||||||

|

|||||||||||

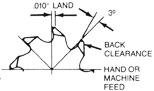

| CUTOFF |

|

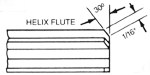

| DRILL | |

|

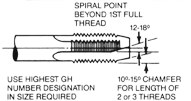

ALL DRILLS MUST HAVE POLISHED FLUTES (NO COATING) FAST SPIRAL FLUTE SPEED* 150 |

| MILL | |||

|

|||

|

|

||||||||||

| * "Speed" denotes Surface Feet per Minute (SFM) --"Feed" denotes Feed per Revolution In Inches (FPR). | ||||||||||

| COOLANT AND CUTTING OIL

RECOMMENDATIONS COOLANT: All operations may be performed with soluble oil, 1

part to 50 parts water, applied as a spray mist. CUTTING OIL: NOT recommended when machining copper alloys except on screw machine operations where it performs as a coolant and lubricant. To prevent metal oxidation, finished parts MUST be cleaned with a detergent-type solvent. GRINDING RECOMMENDATIONS |

|

|

|

|

Copyright © 2024 by Performance Alloys &

Services, Inc |